You fill a glass with water, and it looks perfectly clear. An hour later, the same glass shows an orange-brown tint. Your white sink has rust-colored stains no amount of scrubbing removes. Laundry comes out with mysterious brown spots. Welcome to life with iron in your well water—one of the most common and frustrating well water problems rural homeowners face.

Iron might not pose immediate health dangers, but it wreaks havoc on your home, appliances, clothing, and fixtures. Understanding what type of iron you’re dealing with and choosing the right treatment makes the difference between crystal-clear water and constant frustration with staining and equipment damage.

What Causes Iron in Well Water?

Iron is the fourth most abundant element on Earth. It exists naturally in soil and rock formations. As groundwater travels through iron-bearing geological layers, it dissolves iron from these minerals. Your well simply taps into this iron-enriched water.

Geographic Patterns: Certain areas have higher iron concentrations due to local geology. The Midwest, parts of the Northeast, and regions with significant iron ore deposits typically see higher iron levels. Older wells drilled through iron-rich layers also tend to have more iron.

Well Depth Matters: Deeper wells sometimes encounter different aquifer layers with varying iron content. Shallow wells might have less iron but more surface contamination. There’s no reliable way to predict iron levels without testing—geography and depth provide clues, but testing is the only certainty.

Seasonal Variations: Iron levels can fluctuate seasonally as water tables rise and fall, changing which geological layers your well draws from. Some homeowners notice worse iron problems during dry summers when wells pull from deeper, more mineral-rich zones.

Types of Iron: Why It Matters

Not all iron in water behaves the same way. The type of iron you have determines which treatment methods work.

Ferrous Iron (Clear Water Iron)

This dissolved iron remains invisible when first drawn from your well. Water looks perfectly clear in the glass. But expose that water to air, and within minutes to hours, the iron oxidizes—turning the water yellow, orange, or brown.

Characteristics:

- Water appears clear initially

- Develops color when sitting or exposed to air

- Often has a metallic taste

- No particles visible

- Passed through filters easily when dissolved

Why It Happens: Deep underground, water lacks oxygen. Iron stays in its ferrous (dissolved) state. When pumped to the surface and exposed to air, oxygen converts ferrous iron to ferric iron—the visible, staining kind.

Treatment Challenge: Standard sediment filters can’t catch dissolved iron—you’re trying to filter something that’s not yet a particle. Treatment must oxidize the iron first, converting it to a filterable form.

Ferric Iron (Red Water Iron)

This oxidized iron already exists as particles in your water. Pour a glass and it immediately appears red, orange, or brown. The iron has oxidized underground, usually due to contact with oxygen-rich water or certain bacteria.

Characteristics:

- Water is discolored when drawn

- Particles settle to bottom of glass

- Leaves immediate stains

- Can be filtered with sediment filters

- Sometimes accompanied by red slime

Why It Happens: Oxygen reached your aquifer somehow—maybe through a compromised well cap, mixing with surface water, or aerobic bacteria activity. The iron oxidized before reaching your tap.

Treatment Advantage: Since iron is already in particle form, mechanical filtration can remove it. This is generally easier to treat than ferrous iron.

Iron Bacteria

These naturally occurring bacteria feed on iron, creating thick, slimy deposits. They don’t cause illness, but they create serious nuisance problems and accelerate iron precipitation.

Characteristics:

- Reddish-brown or rainbow-colored slime

- Toilet tanks develop thick, slimy coating

- Stringy, jelly-like masses in water

- Musty or swampy odor

- Frequent clogging of filters and fixtures

Where They Live: Iron bacteria colonize wells, pipes, water heaters, and any surface with consistent water contact. Once established, they’re difficult to eliminate completely.

Treatment Challenge: Standard iron removal doesn’t kill bacteria. You need disinfection (chlorination or shock treatment) combined with iron filtration. Physical removal of biofilm from well and plumbing is often necessary.

Combination Issues

Many homeowners deal with multiple types simultaneously—ferrous iron in the water that supports bacterial growth, creating ferric iron and biofilm. These complex situations require multi-stage treatment approaches.

How Much Iron Do You Have?

Testing reveals your exact iron concentration, measured in parts per million (ppm) or milligrams per liter (mg/L)—these are equivalent measurements.

EPA Secondary Standard: 0.3 ppm

This isn’t a health standard—it’s an aesthetic guideline. Iron becomes noticeable in taste, odor, and staining around 0.3 ppm. Many homeowners find even lower levels objectionable.

Interpreting Your Results:

0.0-0.3 ppm: Minimal iron. You might not notice staining. Most people don’t treat water at this level. Occasional light staining on fixtures is possible but manageable with regular cleaning.

0.3-1.0 ppm: Noticeable iron. Expect light staining in toilets and sinks. Laundry may develop faint discoloration. Metallic taste becomes apparent. Treatment recommended if staining bothers you.

1.0-3.0 ppm: Moderate iron. Significant staining problems. Orange residue in toilets, sinks, and tubs. Laundry ruined regularly. Water has obvious metallic taste. Iron removal system definitely recommended.

3.0-10.0 ppm: High iron. Severe staining. Appliances damaged by iron buildup. Water looks discolored. Iron removal essential—untreated water causes serious damage.

Over 10.0 ppm: Extreme iron. Water appears obviously discolored. Requires professional-grade treatment systems. May need multiple treatment stages. Sometimes indicates well construction problems.

Effects of Iron on Your Home

Staining Damage

Iron staining isn’t just unsightly—it’s permanent if left untreated. Orange and brown stains oxidize into fixtures, becoming increasingly difficult or impossible to remove over time.

Bathroom Fixtures: Toilets develop rings and streaks. Sinks and bathtubs show rust patterns. White porcelain turns dingy orange-brown. Even new fixtures stain within weeks of installation.

Kitchen Sinks: Stainless steel shows rust spots. White or light-colored sinks become permanently discolored. Dishes washed in iron-laden water may develop spots.

Shower Doors and Tiles: Glass shower doors accumulate orange film. Grout between tiles turns rust-colored. These surfaces require constant cleaning to maintain appearance.

Laundry Problems

Iron in washing machines causes multiple issues. Clothes develop rust stains—small brown spots that appear on white and colored fabrics. These stains set permanently with heat from dryers.

White clothing yellows. Fabrics feel rough and stiff. Dark colors fade faster due to iron oxidation accelerating fiber breakdown. Washing machine interiors rust faster, reducing appliance lifespan.

Even using bleach to remove stains makes problems worse—bleach accelerates iron oxidation, setting stains more deeply into fibers.

Appliance Damage

Iron accumulates inside water heaters, dishwashers, and washing machines. These deposits reduce efficiency, increase energy costs, and shorten equipment life dramatically.

Water Heaters: Sediment from iron settles at the bottom, insulating water from heating elements. Your heater works harder, using more energy. Elements burn out faster. Tank capacity decreases as sediment accumulates. Anode rods deteriorate more quickly.

Dishwashers: Spray arms clog with iron deposits. Dishes come out with spotting and film. Heating elements scale over, reducing cleaning effectiveness. Internal components corrode faster.

Coffee Makers and Appliances: Any appliance using water suffers. Coffee tastes metallic. Ice makers produce discolored ice. Small appliances fail prematurely due to mineral buildup.

Plumbing System Impact

Iron deposits gradually narrow pipe diameter, reducing water pressure. Aerators on faucets clog constantly, requiring frequent cleaning or replacement. Shut-off valves seize from iron buildup, making repairs difficult.

In severe cases, pipes require replacement due to iron accumulation. This happens more commonly in galvanized steel pipes, which are already prone to rust internally.

Water Taste and Cooking

Water with over 0.3 ppm iron tastes metallic. Coffee, tea, and other beverages develop off-flavors. Cooking vegetables in iron-rich water can darken their color. Pasta and rice may take on slight discoloration.

While not harmful, this affects quality of life. Cooking and drinking water should taste clean and fresh—iron interferes with this basic expectation.

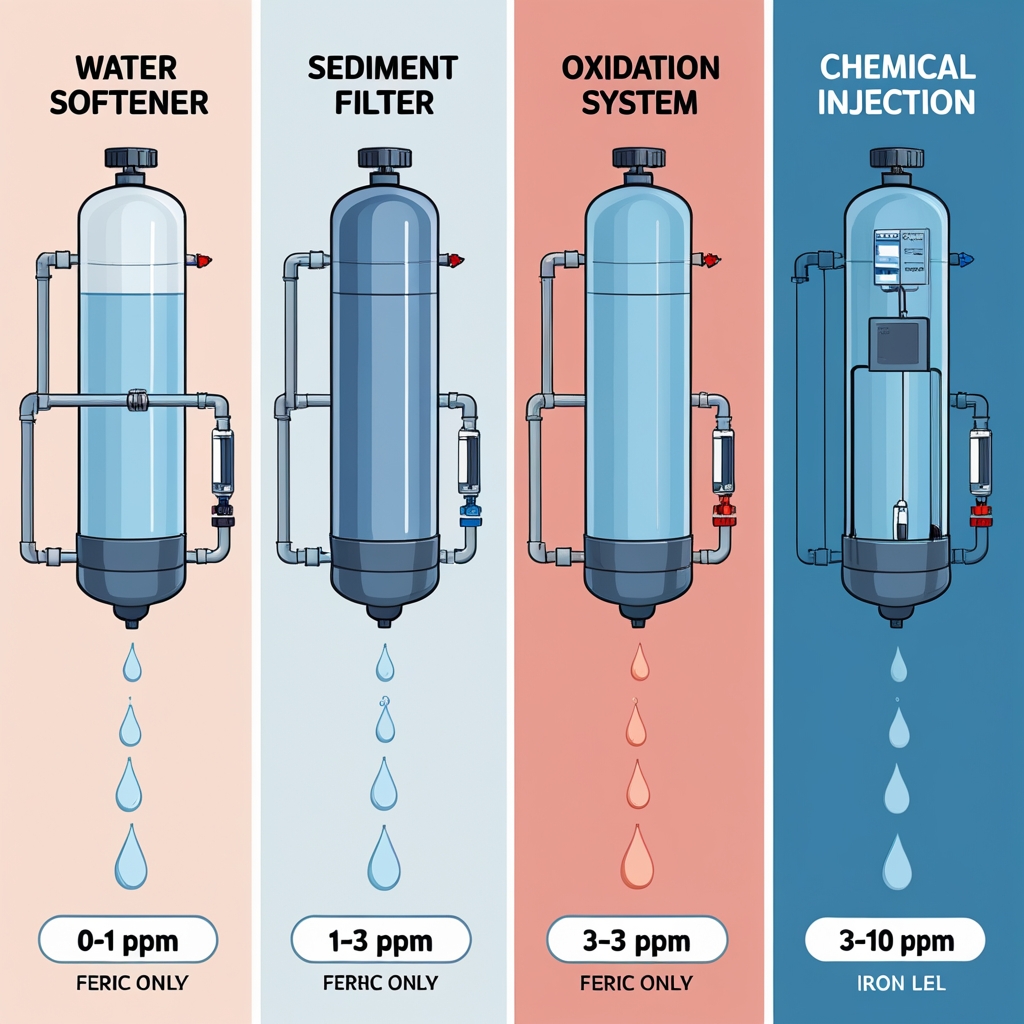

Treatment Options for Different Iron Levels

For Light Iron (0.3-1.0 ppm)

Water Softener: Standard water softeners remove small amounts of ferrous (dissolved) iron—typically up to 0.5-1.0 ppm. The resin that removes hardness also exchanges iron ions.

However, iron fouls resin faster than calcium and magnesium. Your softener requires more frequent regeneration and periodic resin cleaning with iron-removing solutions. Eventually, heavy iron exposure ruins the resin, requiring replacement.

Best Scenario: If you need a water softener anyway for hardness, and iron is under 1 ppm, this might handle both issues. Monitor resin condition and clean it quarterly with specialized cleaning solutions.

Sediment Filter (For Ferric Iron Only): If your iron appears as particles when drawn, a 5-micron sediment filter captures most of it. This works only for already-oxidized (ferric) iron.

Replace cartridges more frequently than normal—monthly or even more often depending on iron levels and water usage.

For Moderate Iron (1.0-3.0 ppm)

This range requires dedicated iron removal systems. Water softeners alone struggle at these levels.

Oxidation + Filtration Systems: These systems inject air into your water, oxidizing ferrous iron to ferric form. The oxidized iron then filters out through specialized media.

How They Work:

- Air injection: Pump adds air to water

- Contact tank: Water and air mix, oxidizing iron

- Filter media: Oxidized iron particles trapped

- Backwash: System periodically cleans itself

Effective for ferrous iron, some ferric iron, and small amounts of manganese (often present with iron). These systems require electricity, a drain line, and adequate water pressure.

Manganese Greensand Filters: Greensand is natural material coated with manganese oxide, which oxidizes iron and manganese. Water flows through the greensand bed, converting dissolved iron to filterable particles.

Periodically, potassium permanganate regenerates the greensand, restoring its oxidizing capacity. These systems work well for moderate iron and manganese.

Requires ongoing potassium permanganate purchases (about $30-60 every few months) and regular backwashing with adequate water pressure.

For High Iron (3.0-10.0 ppm)

Higher iron levels demand more aggressive treatment approaches.

Chemical Feed Pump Systems: These systems continuously inject oxidizing chemicals (usually chlorine or hydrogen peroxide) into your water. The chemicals oxidize iron, which then filters out.

Process:

- Chemical injection: Pump adds oxidizer to water line

- Contact/retention tank: Allows oxidation to complete

- Filter: Removes oxidized iron particles

- Carbon filter: Removes residual chemical

Very effective for high iron, bacteria, and manganese. Requires chemical refills, maintenance, and proper safety handling. Professional installation recommended.

Catalytic Carbon Filters: Specialized activated carbon with catalytic properties oxidizes and filters iron without chemical injection. Works for moderate-to-high iron levels.

Simpler than chemical systems—no chemicals to handle. Requires regular backwashing and eventual carbon replacement (every 5-10 years depending on iron levels).

Multi-Stage Systems: Severe iron often requires combinations: pre-filtration for particles, oxidation stage, filtration stage, and sometimes post-filtration carbon to remove any taste or odor from treatment chemicals.

Professional system design ensures all stages work together efficiently for your specific water chemistry.

For Extreme Iron (Over 10.0 ppm)

Extremely high iron may indicate well problems—corrosion of well casing or pump components, or unusual geology. Professional well inspection should verify the source.

Treatment requires robust, professionally-designed systems, often combining multiple technologies. Some situations benefit from well rehabilitation to reduce iron at the source rather than treating it all post-pumping.

Special Case: Iron Bacteria Treatment

Iron bacteria add complexity. Even if you remove dissolved iron, bacteria continue producing biofilm and accelerating iron problems.

Shock Chlorination: Temporarily treats bacteria by flooding your well and plumbing with strong chlorine solution. Kills bacteria throughout the system. However, bacteria often return because they colonize deep in well screens and pipes.

Shock chlorination works as a periodic treatment (every 6-12 months) to control bacteria between other treatments. It’s not a permanent solution alone.

Continuous Chlorination: Installing a chemical feed system that constantly maintains low chlorine levels (similar to pool treatment) prevents bacterial regrowth. Combined with filtration, this provides long-term iron bacteria control.

Requires monitoring, chemical refills, and carbon post-filtration to remove chlorine taste before use.

UV Sterilization: Ultraviolet light kills bacteria as water passes through. However, UV alone doesn’t remove iron or biofilm already established. Use UV as part of a comprehensive system after removing suspended iron (UV only works in clear water).

Physical Well Cleaning: Professional well companies can physically remove biofilm from well casings and screens using brushes and high-pressure washing. This, combined with chemical treatment, provides the best long-term control.

DIY vs. Professional Treatment

What Homeowners Can Handle

Sediment Filtration: Installing whole-house sediment filters is straightforward DIY work if you’re comfortable with basic plumbing. Pre-made systems from hardware stores work for light ferric iron.

Water Softener Installation: Moderately handy homeowners can install water softeners. This handles light ferrous iron if you’re already addressing hardness.

Maintenance: Changing filters, adding salt to softeners, and refilling chemical tanks are simple ongoing tasks most homeowners handle themselves.

When to Hire Professionals

Complex Systems: Chemical injection, advanced oxidation, multi-stage systems—these require professional design and installation. Water chemistry analysis ensures the right system for your specific iron type and concentration.

Well Issues: If testing suggests well components are corroding and contributing iron, professional well inspection and potential rehabilitation work is necessary. Don’t attempt well work yourself—licensing requirements exist for safety reasons.

Iron Bacteria: Successfully treating established iron bacteria colonies typically requires professional-grade shock chlorination equipment and expertise. DIY shock chlorination helps but rarely eliminates heavy bacterial growth.

High Iron Levels: Over 3 ppm generally benefits from professional system design. The investment in proper equipment pays off in effective treatment and fewer headaches.

Costs: What to Expect

Testing:

- Basic iron test: $15-30

- Comprehensive water analysis: $100-200

Treatment Systems:

- Sediment filters (DIY): $100-300

- Water softener: $500-2,500

- Air injection oxidation: $1,000-3,000

- Greensand filter: $1,200-2,500

- Chemical injection system: $1,500-4,000

- Multi-stage systems: $3,000-8,000+

Ongoing Costs:

- Sediment filters: $20-60/year

- Water softener salt: $50-150/year

- Greensand regenerant: $30-100/year

- Chemical feed: $50-200/year

- Professional maintenance: $100-300/year

Well Work (If Needed):

- Shock chlorination: $300-600

- Well cleaning: $500-1,500

- Well rehabilitation: $1,000-5,000

Higher initial investment in proper systems saves money long-term through reduced appliance replacement, less cleaning product use, and avoiding laundry replacement costs.

Prevention and Maintenance

Protecting Your Investment

Once you’ve installed iron removal, protect it:

Follow Maintenance Schedules: Set reminders for filter changes, regeneration chemical refills, and backwashing cycles. Skipping maintenance reduces effectiveness and can damage systems.

Monitor Performance: Watch for returning staining or taste issues—early indicators that something needs attention. Don’t wait until problems are severe.

Keep Records: Document when you changed filters, added chemicals, or performed maintenance. This helps identify patterns and ensures timely service.

System-Specific Maintenance

Sediment Filters: Check pressure drop monthly. Replace cartridges when pressure drops 10+ PSI or manufacturer recommends. Inspect housings for cracks or leaks during changes.

Oxidation Systems: Verify air injection works—you should hear air moving when system operates. Check air volume in contact tank periodically. Replace air injection venturi if it clogs.

Greensand Systems: Maintain correct potassium permanganate levels. Regenerate per manufacturer schedule. Backwash thoroughly to remove accumulated iron.

Chemical Systems: Check chemical tank levels weekly. Verify pump operation. Test injection rate annually to ensure proper dosing. Replace check valves as needed.

When Treatment Isn’t Working

System Still Staining:

- Verify you’re treating the right iron type

- Check that system is sized for your iron level

- Ensure water pressure is adequate

- Confirm maintenance is current

- Test water post-treatment to verify removal

Performance Degraded:

- Replace fouled media or resin

- Check for iron bacteria (biofilm in tanks)

- Verify regeneration cycles completing

- Inspect for equipment failures

New Problems After Treatment:

- Low water pressure (system undersized or clogged)

- Different taste (carbon filter needed post-treatment)

- Water looks different (normal after treatment but unfamiliar)

Work with your equipment supplier or a water treatment professional to troubleshoot. Most issues have straightforward solutions once properly diagnosed.

Frequently Asked Questions

Q: Is iron in water dangerous to drink?

A: No, iron isn’t a health hazard at levels typically found in well water. The EPA’s 0.3 ppm guideline is aesthetic, not health-based. However, very high iron levels can indicate well corrosion, which might introduce other contaminants worth investigating.

Q: Will a Brita filter remove iron?

A: No. Pitcher filters aren’t designed for iron removal. They might trap small amounts of ferric iron particles temporarily, but they’ll clog quickly and won’t remove dissolved ferrous iron at all.

Q: Can I just use bottled water and not treat iron?

A: For drinking and cooking, yes. But iron will continue damaging appliances, staining fixtures, and ruining laundry. Whole-house treatment addresses these issues. Some homeowners use bottled water while budgeting for proper treatment systems.

Q: Will iron removal also remove hardness?

A: Not necessarily. Some systems remove both, others don’t. If you have both iron and hardness issues, plan for treatments that address both or install separate systems for each.

Q: My water clears up after sitting—is the iron really a problem?

A: Yes. Even if water clears in a glass, iron is oxidizing onto everything it contacts—inside your pipes, on your fixtures, in your appliances. The damage accumulates invisibly until it’s severe.

Q: How long do iron removal systems last?

A: With proper maintenance, most systems last 10-15 years before needing major component replacement. Media beds typically need renewal every 5-10 years depending on iron levels and water usage.

Taking Action

Living with iron in your water means constant battles against staining, premature appliance failure, and water quality complaints. Treatment transforms this frustrating situation into manageable routine maintenance.

Start with testing—know exactly what you’re dealing with. For iron under 1 ppm, a water softener might suffice if you’re treating hardness anyway. For 1-3 ppm, dedicated iron removal systems work well. Over 3 ppm, professional system design ensures you get effective treatment matched to your specific water chemistry.

Don’t wait until iron has caused expensive damage. The longer you delay treatment, the more permanent staining and wear accumulate. Your next water heater replacement, set of white towels, or toilet cleaning session reminds you why addressing iron now makes sense.

With the right treatment and maintenance routine, iron becomes a non-issue. Your water runs clear, appliances last their expected lifespan, and you stop wasting time fighting rust stains. That’s the difference proper iron treatment makes.

📢 Affiliate Disclosure

This article contains affiliate links to products we recommend. We may earn a commission from purchases made through these links at no additional cost to you.

We use advanced technology to scan thousands of products and their ratings. Our experts then combine this AI data to give you instant, top-rated recommendations you can trust.

⚠️ General Disclaimer

This article provides general information about well water systems and is not intended as professional advice. Well water systems vary significantly, and water quality issues can be complex.

For serious water quality concerns, system installations, or health-related issues, always consult with licensed professionals including well contractors, water treatment specialists, or healthcare providers as appropriate.